Environmental Conservation and Management

The JVCKENWOOD Group has set the following target for the prevention of pollution and the proper management of toxic chemicals.

Proper management of chemical substances (hazardous chemical substances)

・ Define and manage “environmentally controlled substances” based on in-house standards determined to have significant impacts (aspect) on the global environment and human body.

Management of Chemical Substances in Procurement

At the JVCKENWOOD Group, we recognize that we should share information on chemical substances contained in products across the supply chain to ensure their proper management and continue to comply with expanding regulations. Therefore, the JVCKENWOOD Group was involved from the beginning in the establishment and introduction of chemSHERPA, an information sharing scheme led by the Ministry of Economy, Trade and Industry, and is making active efforts to facilitate the sharing of information on chemical substances contained in products across the private sector. For details of our comprehensive approach to environmentally friendly procurement and notes for submitting chemSHERPA data, please see Green Procurement.

Management of Chemical Substances in Business Activities

The JVCKENWOOD Group recognizes that it is responsible as a global corporation for minimizing the impact of chemical substances on people and ecosystems by properly managing chemical substances in accordance with international regulations. Therefore, we work to monitor and control the use of toxic chemicals in the production process, look for alternative chemicals, and review and improve the working environment. These efforts also involve our suppliers.

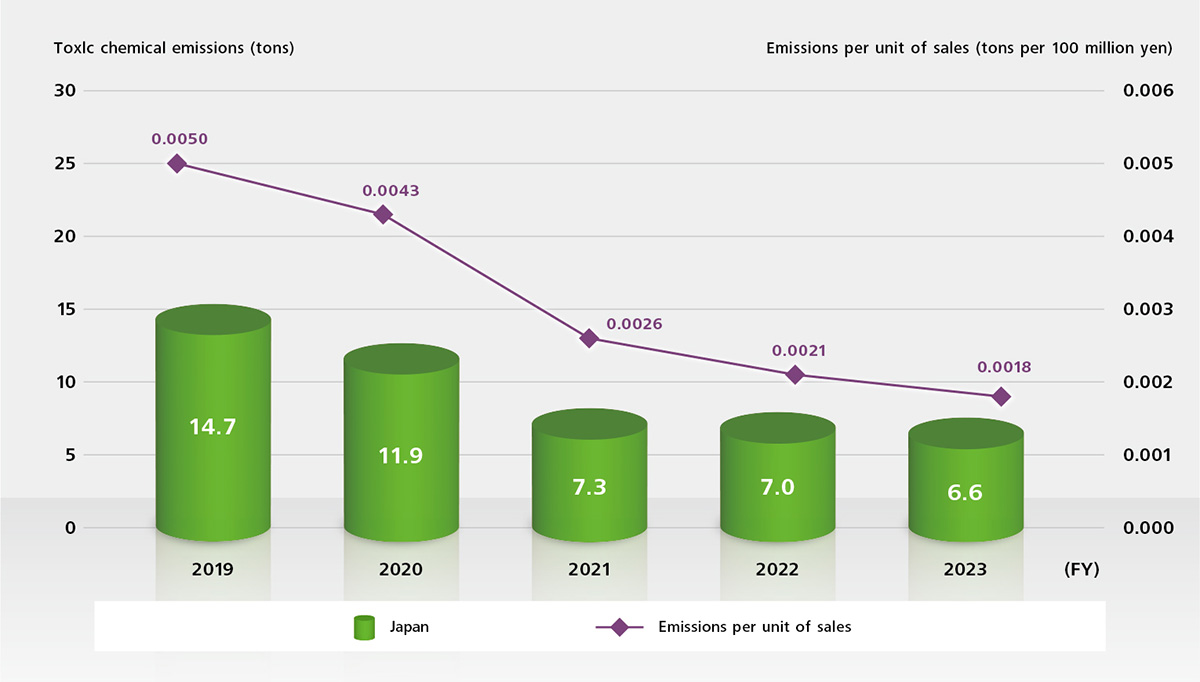

In FY2023, we emitted 6.6 tons* of toxic chemicals, all of which were properly disposed of as specially controlled industrial waste. We will continue working to promote proper management of toxic chemicals and reduce emissions.

Going forward, we will continue to develop, manufacture, and sell environmentally and human friendly products around the world so that customers can confidently use our Group’s products.

Toxic chemical emissions (FY2019–2023)

Coverage1: Specially controlled industrial waste generated in Japan

Coverage2: The figures indicate the amount of waste disposed of in each fiscal year (and do not equal the actual emission amounts)

Efforts to Reduce the Emissions of Volatile Organic Compounds (VOCs)

We are making efforts to reduce the emissions of volatile organic compounds (VOCs) that cause air pollution. In FY2023, we worked on reduction initiatives with the target of reducing VOC emissions to 5.7 tons or less, the volume of emissions in FY2022. The actual volume was 5.8 tons, slightly over the target.

VOC emissions (FY2019-2023)

Unit:t

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|---|

| VOC emissions | 16.4 | 10.4 | 6.2 | 5.7 | 5.8 |

Coverage: Business centers and manufacturing companies in Japan

Shinwa Industries (China) Ltd. responded to the government of China’s requirement to reduce emissions of VOC by adding a two-stage activated carbon adsorption system to the exhaust vents at the Jiangbei Business Center’s painting plant. The project received completion approval in 2022 and has yielded the specific benefits of a VOC emissions rate reduction from 0.1 kg/h to 0.013 kg/h. Assuming 6,000 hours of annual production, this reduces VOC emissions by 0.522 tons/year.

Shinwa Industries Ltd. Two-stage activated carbon absorber

*Limited to specially controlled industrial waste generated in Japan