Waste and Plastic Reduction

Waste and Plastic Management Goals

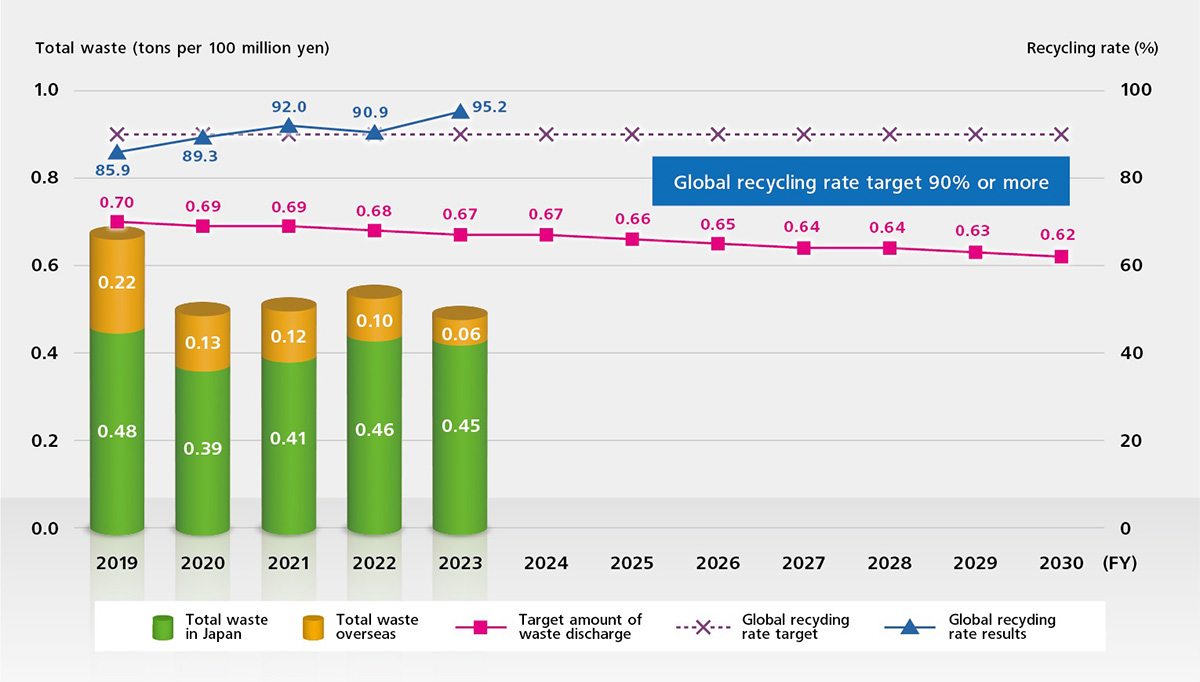

The JVCKENWOOD Group is actively engaged in initiatives such as waste reduction, diligently disassembling and sorting waste generated in the production processes and reusing it within the company or turning it into valuables. As a result, the Group’s business in Japan has achieved a recycling rate of 99.9% (FY2023), and the waste generation inside and outside Japan also declined. Our goal had been to reduce waste generation by 1% from the FY2019 level annually through FY2030. We have already achieved this goal and established the following targets in order to move forward with zero emissions globally and proceed further with reduction of total waste generation and recycling.

■Reduction of waste (waste recycling rate)

- ・Maintain the recycling rate of at least 90% (total, global)

■Reduction in waste generation

- ・11% reduction from FY2019 levels by FY2030 (per unit of net sales, global)

■Reduction of plastics

- ・Plastic consumption volume for containers and packaging 35.9% reduction from FY2019 levels by FY2030(total, global)

Waste and Plastics Reduction Performance

Reduction of waste emissions (per unit of net sales) and recycling rates (FY2019-2023)

Total waste and recycling rates (FY2019-2023)

FY2019 |

FY2020 |

FY2021 |

FY2022 | FY2023 | |

|---|---|---|---|---|---|

| Total waste (Thousand tons) | |||||

Japan |

1.4 |

1.1 |

1.2 |

1.5 | 1.6 |

Overseas |

0.6 |

0.3 |

0.3 |

0.4 | 0.4 |

Global |

2.0 |

1.4 |

1.5 |

1.9 | 1.9 |

| Recycling rate (%) | |||||

Japan |

99.7 |

99.8 |

99.7 |

99.9 | 99.9 |

Overseas |

55.8 |

57.0 |

65.6 |

51.5 | 61.1 |

Global |

85.9 |

89.3 |

92.0 |

90.9 | 95.2 |

Coverage: refer to “Total waste by business location”

Emissions per unit of sales (FY2019-2023)

1,000 tons/100 million yen

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|---|

Global |

0.70 |

0.51 |

0.53 |

0.56 | 0.51 |

Coverage: refer to “Total waste by business location”

Total waste by business location (FY2019-2023)

Unit: t

Japan/ |

Company name and location | FY2019 | FY2020 | FY2021 | FY2022 | FY2023 |

|---|---|---|---|---|---|---|

| Japan | Head Office & Yokohama Business Center | 327 |

265 | 270 | 316 | 306 |

| Hachioji Business Center | 124 |

63 | 65 | 77 | 74 | |

| Hakusan Business Center | 55 |

38 | 36 | 82 | 50 | |

| Kurihama Business Center | 61 |

38 | 86 | 172 | 223 | |

| Yokosuka Business Center | 7 |

31 | 23 | 9 | 8 | |

| JVCKENWOOD Yamagata | 25 |

23 | 20 | 21 | 98 | |

| JVCKENWOOD Nagano | 145 |

84 | 129 | 376 | 410 | |

| JVCKENWOOD Nagaoka | 92 |

96 | 96 | 142 | 144 | |

| JVCKENWOOD Creative Media | 342 |

390 | 406 | 304 | 262 | |

| Victor Entertainment | 53 |

31 | 31 | 33 | 40 | |

| JVCKENWOOD Video Tech | 2 |

1 | 1 | 2 | 1 | |

| JVCKENWOOD Design | 0 |

0 | 0 | 0 | 0 | |

| Other affiliate companies | 161 |

- | - | - | - | |

| Malaysia | JVCKENWOOD Electronics Malaysia Sdn. Bhd. | 101 |

48 | 56 | 63 | 55 |

| Thailand | JVCKENWOOD Electronics (Thailand) Co., Ltd. | 15 |

40 | 62 | - | - |

| JVCKENWOOD Optical Electronics (Thailand) Co., Ltd. | 79 |

62 | 63 | 57 | 57 | |

| Indonesia | PT JVCKENWOOD Electronics Indonesia | 173 |

123 | 110 | 128 | 83 |

| People’s Republic of China | Shanghai Kenwood Electronics Co., Ltd. | 180 |

74 | 46 | 53 | 30 |

| Singapore | JVCKENWOOD Technologies Singapore Pte. Ltd. | 100 |

86 | 0 | 49 | - |

| Overall total | 2,028 | 1,406 | 1,499 | 1,883 | 1,841 | |

Improvement of Waste Recycling Rate

Waste Recycling (Hakusan Business Center)

The Hakusan Business Center works to reduce and recycle waste in accordance with instructions from the local government. All recyclable waste is recycled by an outsourced waste management provider. Solid waste generated from the business center is collected in recycling bins which are separated into 16 categories and then further sorted into 35 sub-categories in accordance with the waste sorting rules of the business center before it is delivered to the outsourced waste management provider. In FY2023, approximately 90% of the waste collected from the business center was recycled.

Waste recycling bins (on each floor)

Waste recycling containers (for valuables, etc.)

Promotion of Recycling of Industrial Waste Through Acquisition of Industrial Waste Licenses (Collection, Transportation, Reloading, and Storage) (JVCKENWOOD Service (Japan))

At JVCKENWOOD Service (Japan), we have been utilizing licenses for the collection and transportation of industrial waste acquired in FY2023 (Yokosuka City, Kanagawa Prefecture) to promote sustainability management. In this way, we are contributing to the conservation of the global environment and the achievement of a healthy and sustainable society through our products, services, and environmental activities.

We reduced the amount of waste by developing new connections with a broad range of recycling business operators for metals, plastics, paper, etc., and increasing the amount of waste that can be sold.

Reduction in Waste Generation

Efforts to Reduce Office Paper Consumption

As part of the efforts to promote environmentally friendly corporate management, the JVCKENWOOD Group has installed large monitors and projectors in meeting rooms to improve the quality of meetings and reduce paper usage for meetings and other purposes to protect resources and reduce waste.

Moreover, our management teams take the initiative to promote paperless meetings by introducing tablets and IT devices at Board of Directors meetings, thereby reducing paper-based meeting materials. Going forward, we will continue working to reform the meeting process to enhance productivity and reduce environmental loads.

At the paperless Board of Directors meeting

Meeting room at Value Creation Square

Initiatives to Reduce Waste at Domestic Order Booking Centers

JVCKENWOOD's order booking centers have moved to remote operations for fax orders. The purpose of this project is to increase awareness of the value of recycled materials, and by switching to paperless operations for the entire fax ordering process, it also saves on costs for paper, copy machine maintenance, and storage. The server can be accessed from anywhere with the proper telecommunications environment and is expected to improve efficiency by facilitating responses to pandemics and other unforeseen disasters, and avoiding the backups that can be experienced when order booking is concentrated at a single location.

Reduction of the Use of Plastics

There is a growing demand in society for resource recycling related to plastics following the enforcement of the Plastic Resource Circulation Act from April 2022. The JVCKENWOOD Group is also taking various measures to reduce the amount of plastic used in its products and packaging materials.

We have set a target of reducing plastic consumption volume for containers and packaging by 35.9% by 2030 compared with FY2019, and as of FY2023, we had achieved a 29.9% reduction compared with FY2019.

Plastic consumption volume for containers and packaging (FY2019-2023)

Unit:Thousand tons

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|---|

Global |

146.0 |

146.3 |

127.8 |

101.7 | 102.5 |

Initiatives to Reduce the Use of Plastic Materials Related to the DRV-EM4800 Electronic Mirror Dashcam

We are reducing the amount of plastic materials used in the DRV-EM4800 electronic mirror dashcam for the domestic aftermarket.

In the past, card cases and adapters were bundled with the micro SD cards. However, the DRV-EM4800 electronic mirror dashcam, which was released for the domestic aftermarket at the end of September 2023, is shipped with the micro SD card inserted into the mirror main body of the mirror, eliminating the bundling and reducing the use of plastic materials. This thereby contributes to the reduction of CO₂ emissions and saves energy.

Plastic micro SD card case (left) no longer included in the package

Plastic micro SD card adapter (right) no longer included in the package

Participating in External Initiatives

We support the Ministry of the Environment’s Plastics Smart Campaign and Kanagawa Prefecture’s Kanagawa No Plastic Waste Declaration. Designed to encourage voluntary initiatives that address the increasingly serious problem of ocean plastic pollution, the Plastics Smart Campaign spreads the word widely on various initiatives being implemented in Japan by companies, industry groups, local governments, etc. The Kanagawa No Plastic Waste Declaration is a project launched by Kanagawa Prefecture in conjunction with this campaign as part of its efforts to achieve the SDGs. It aims to reduce non-recyclable plastic waste to zero, with a particular focus on microplastics, among other marine pollution issues. In promoting sustainability, we are working to achieve the SDGs across economic, social, and environmental dimensions, and have joined the project as a company operating in the prefecture that is implementing specific initiatives such as making environmentally friendly products and raising awareness among its employees.

Coverage: refer to “Total waste by business location”