Monozukuri (Manufacturing) Reforms

New Value Creation through Manufacturing

Along with the formulation of the medium-term management plan VISION2023, we have newly established Engineering Innovation Department, as a head office function that serves as a manufacturing skill group linked to business domains, responsible for design environment reform, advanced skill acquisition regarding production technology, quality control functions, and strategic material procurement.

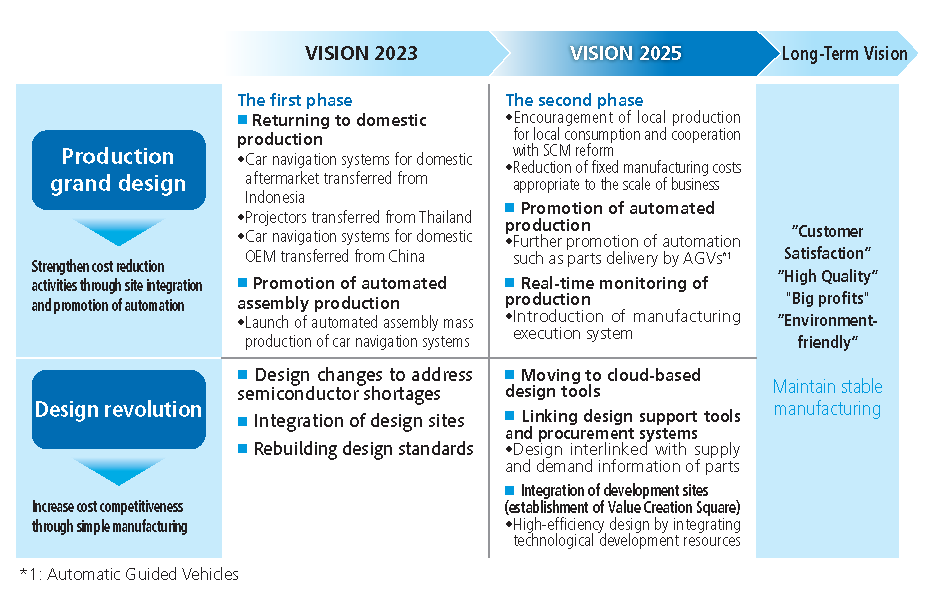

Under the newly formulated VISION 2025, we will continue promoting the integration of production bases, promotion of automated production, encouragement of local production for local consumption, and establishment of a supplier ecosystem. In this regard, we have been working on "production grand design" and "design revolution" that fit the total production volume and total man-hours. We aim to establish manufacturing standards in which anyone is enabled to design, any place is suited to produce, production systems are optimized and standardized, shipping quality is ensured, and work styles are diversified.

Production Grand Design

The JVCKENWOOD Group has established the following three perspectives as its grand design in promoting Monozukuri (Manufacturing) Reforms

■ Acceleration the return to domestic production, including encouragement of local production for local consumption, cooperation with SCM reform, and reduction of fixed manufacturing costs appropriate to the scale of business

■ Further promotion of automated production, such as parts delivery by AGVs

■ Real-time monitoring of production, including the introduction of manufacturing execution systems

Design Revolution

The JVCKENWOOD Group has working on three design reforms in promoting Monozukuri (Manufacturing) Reforms

■ Moving to cloud-based design tools

■ Linking design support tools and procurement systems

■ High-efficiency facilities design by integrating technological resources, such as the establishment of Value Creation Square, an integration of development sites.

Progress in Manufacturing Reforms

Among initiatives to return to domestic production, for which we have been working as a part of production grand design, we made decisions at an earlier stage to take on the challenge of realizing a production model based on local production for local consumption, aiming to enhance and redeploy our management assets. Furthermore, in the Communications Systems Business, which is the key to profit generation, we are accelerating further streamlining of design and fostering of earnings power from a total cost perspective, including the commencement of automated production at the Yamagata factory of the "VP8000" tri-band P25 radio, the top-of-the-line model for the North American public safety sector.

While we proceed to reorganize production bases in an accelerated manner, we aim to manufacture products in a way in which the "design environment is standardized and products of any categories can be designed" as well as so that "products of any categories can be produced independent of a particular base."

Returning to Domestic Production (JVCKENWOOD Nagano Corporation)

Although there were great concerns about maintaining the continuity of production activities due to the global economic stagnation caused by the COVID-19, difficulties in procuring parts and materials, especially semiconductors, and disruptions in distribution networks, we made a decision to challenge the realization of a local production for local consumption production model at an early stage under the banner of total cost reform, and as one measure of Monozukuri (Manufacturing) reforms, we dared to return to domestic production and promoted automated production to upgrade our management assets.

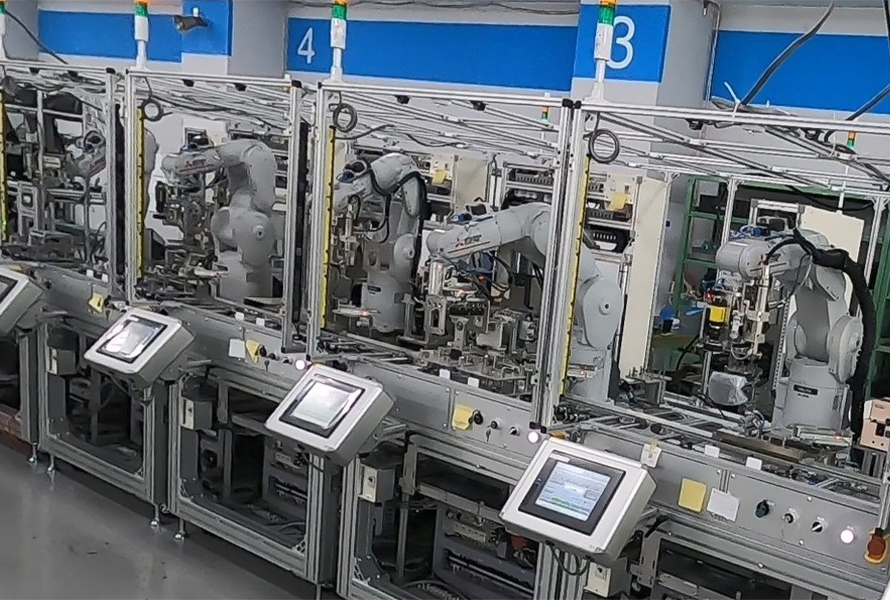

In late February 2022, JVCKENWOOD Nagano began full-scale production of car navigation systems for the domestic aftermarket, including production of navigation systems exclusively for domestic automakers. In FY 2022, we produced more than 300,000 units over the year, including production of navigation systems exclusively for domestic automakers, and the cumulative number of units produced through FY2024 exceeded one million units.

JVCKENWOOD Nagano Corporation

Automated manufacturing line