Manufacturing Reforms

The key to achieving sustainable growth while pursuing the assurance of a safe society and the creation of a moving experience for people in the future lies in design management — the pursuit of customer-oriented value creation in each process of the value chain. Customer-oriented value in manufacturing entails the establishment of stable and resilient manufacturing that balances high quality and the ability to rapidly adapt to the business environment. Based on this mission, we aim to standardize manufacturing in which anyone is enabled to design, any place is suited to produce, production systems are optimized and standardized, shipping quality is ensured, and workstyles are diversified.

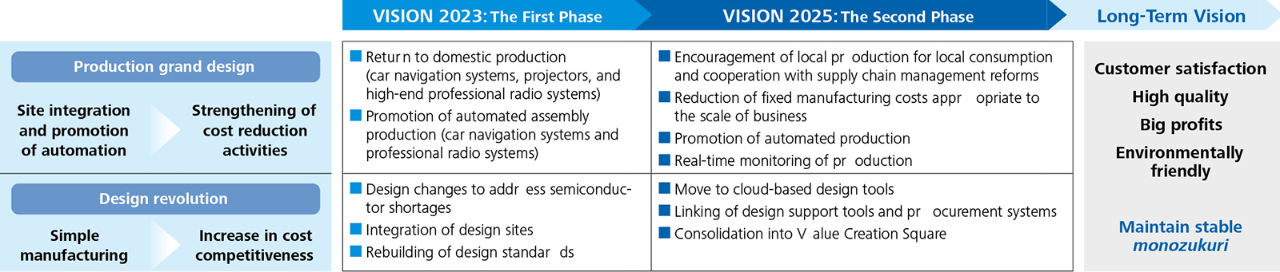

In the future we aim to realize data-driven manufacturing and are promoting comprehensive reforms from upstream to downstream manufacturing that cover production, digital transformation, R&D, and intellectual property. In a continuation of the previous medium-term management plan VISION 2023, we have been working on "production grand design" and "design revolution" tailored to the total production volume and total man-hours outlined in the following road map with the integration of production bases, promotion of automated production, encouragement of local production for local consumption, and establishment of a supplier ecosystem at the core of our strategy.

Production Grand Design

Production grand design aims to reduce costs by promoting the advancement and relocation of production sites and optimizing the production structure. Under phase two of VISION 2025, we are mainly promoting the connection between aspects such as local production for local consumption and supply chain management (SCM), the advancement of automated production that utilizes technology such as automatic guided vehicles, the real-time monitoring of production status through system implementation, and the relocation of production sites to reduce fixed management costs appropriate to the scale of the business. Production sites are relocated based on their adaptability to the key production management factors of quality, cost, delivery, environment (CO2 emissions reduction and human rights), and risks (geopolitical risks and economic security). In the Communications Systems Business in fiscal 2024, we advanced the automation of production of VP8000 portable radios and VM8000 mobile radios for the North American public safety market at the Yamagata Factory.

Moreover, in FY2022 we transferred production of car navigation systems from Indonesian (PT. JVC Electronics Indonesia) and Shanghai (Shanghai Kenwood Electronics Co., Ltd.) factories to JK Nagano, and promoted the automation of manufacturing processes. In October 2024, production volume since the transfer reached 1 million units.

Efforts to Optimize Production Bases and Development Sites

| Timing | Efforts | Readiness for Geopolitical Risk | Foreign Exchange Measures | SCM Optimization | Security Enhancement | Return to Japan | Efficiency / Automation | SDGs / ESG |

|---|---|---|---|---|---|---|---|---|

| February 2022 | Transfer of production of car navigation systems for domestic aftermarket from Indonesia to Nagano Prefecture | ● | ● | ● | ● | ● | ● | ● |

| March 2022 | Transfer of production of projectors from Thailand JKET*1 to Yokosuka City | ● | ● | ● | ● | ● | ● | ● |

| Transfer of production of professional cameras from Thailand JKET to Thailand JKOT*2 and termination of production activities at JKET | ● | ● | ● | ● | ||||

| November 2022 | Transfer of production of car navigation system for domestic OEM from China to Nagano Prefecture | ● | ● | ● | ● | ● | ● | ● |

| January 2023 | Launch of production of tri-band radio in Yamagata Prefecture | ● | ● | ● | ● | ● | ● | ● |

| March 2023 | Transfer of M&T development functions from Singapore and closure of development sites in Singapore | ● | ● | |||||

| September 2023 | Termination of production activity at the Shanghai production base in China | ● | ● | ● | ● | ● | ● | ● |

| October 2024 | Achievement of production of one million car navigation systems following transfer of domestic production to Nagano Prefecture | ● | ● | ● | ● | ● | ● | ● |

- *1 JVCKENWOOD Electronics (Thailand) Co., Ltd.

- *2 JVCKENWOOD Optical Electronics (Thailand) Co., Ltd.

Design Revolution

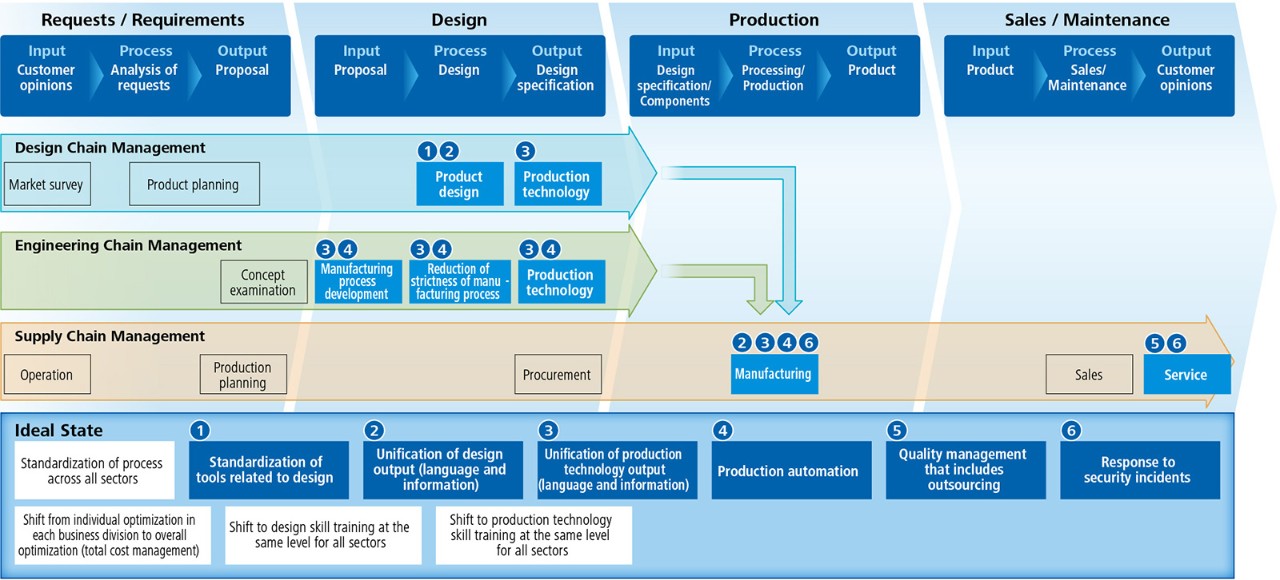

Design revolution aims to enable the design of products, regardless of the business sector, at all production sites and promotes the standardization of the design environment across all departments related to manufacturing. Manufacturing moves through a process where the output (deliverable) completed by receiving input from the preceding process becomes input for the next process. The Group has been standardizing the output by unifying the tools and operations that differ depending on each business division. By this, we have realized data utilization across sectors and reduced management man-hours. We have reduced management costs and improved operational efficiency, creating an environment where anyone can design and produce anywhere.

In fiscal 2024, we concentrated departments, which had been divided between sites by business sector, at Value Creation Square. Unifying the design tools, development environment, and in-Group databases enabled us to effectively utilize design data across sectors. Design data made in a uniform format led to a reduction in management costs and improved operational efficiency in production. We have also realized a reduction in management workload by moving to cloud-based design-related systems. Further, we aim to enhance production and ensure stable quality by standardizing product design that is considerate of automated assembly.

Overview of Design Revolution