Product Quality & Safety

The JVCKENWOOD Group has been working to improve product quality and safety across its supply chains, in all activities from procurement to sales, and has also been active in after-sales customer support.

Quality Principle and Policies

Quality principle

Commit to provide High Quality* products and services that delight and excite our customers.

Quality policies

To assure that Quality originates from management.

Establish and maintain Quality rules and regulations for products. Provide products that live up to our customer’s expectations.

Manufacture safe products.

Consider the environment, both the people and the Earth in manufacturing decisions. Make advanced efforts for continually improving Quality by learning and in all activities.

*High Quality products and services are those that meet the following conditions:

Safety: No personal injury, property damage or fatality shall be caused by our products. It also complies with technical and environmental regulations and takes security measures.

Function: Utility and good usability for customers who purchase our products.

Specification: Product specifications shall be equal to or superior to competitive products.

Reliability: Under normal operating conditions, our product will be free of malfunctions.

Cost effectiveness: Safety, Specifications and Reliability shall be the same or better than competitive products. The product price shall be equal to or better than competitive products.

Initiatives to Improve Product Quality

In order to realize its corporate vision of “creating excitement and peace of mind for the people of the world,” the JVCKENWOOD Group has established a company-wide quality management system based on its quality principle and policies. We are making group-wide efforts that include solving quality issues through collaboration between business units and relevant departments as well as taking expert approaches to product quality improvement at every step, from design and procurement to manufacturing.

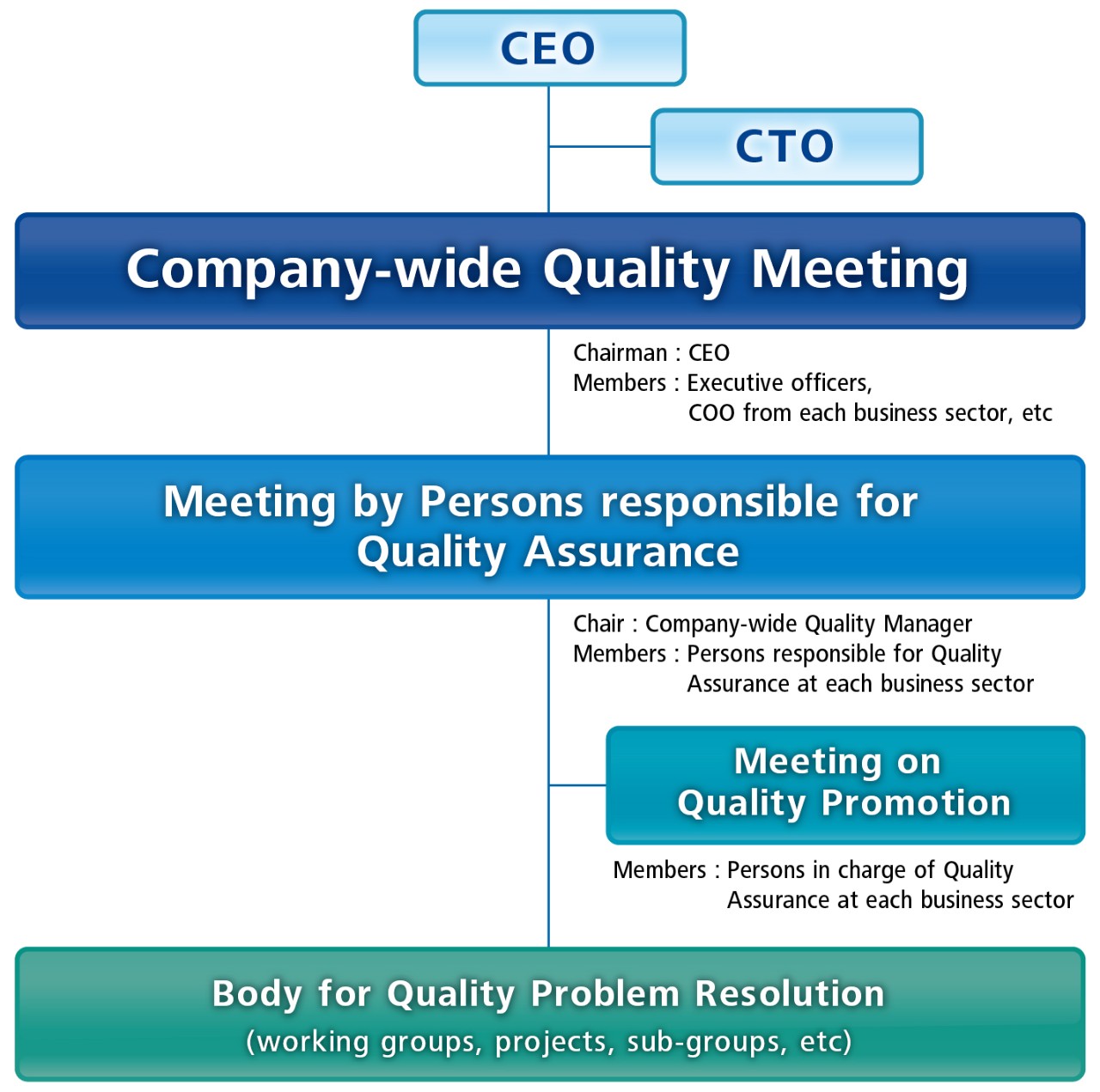

Company-wide quality management

The JVCKENWOOD Group holds semiannual company-wide quality meetings. Chaired by the president (CEO), the meeting is attended by quality management personnel across the Group, including executive officers and business unit managers, who share the quality status of all business operations and make prompt decisions aimed at solving quality problems. In order to implement the policies and strategies adopted at the company-wide quality meeting, company-wide quality officer meetings are held. There, quality assurance officers from all business units determine specific quality activities and, when necessary, establish quality-related problem-solving working groups, projects, sub-committees, etc. in order to solve quality problems.

Company-wide Quality Assurance Management System

At Company-wide Quality Meeting

Design quality initiatives

Each business unit’s design department has a management system for ensuring product quality and safety at each stage of the design process to pave the way to commercialization as well as ensure that relevant departments work together to implement verification procedures. At the beginning of the design process, we identify quality problems and challenges in light of customer feedback on previous models, research what new technologies and parts are available, and develop a quality standard for the new model. In this way, when developing a new product, qualified personnel ensure that the quality standard is met at each stage of the commercialization process and make corrections as necessary in order to improve customer satisfaction and prevent quality problems from ever occurring. At the product evaluation stage, we use various types of testing equipment to assess product performance, including durability under all conditions of intended use.

We are also actively working on developing more advanced product evaluation techniques, such as a more accurate, automated quality evaluation technology employing AI, to replace conventional sensory evaluation using human senses (sight, sound, taste, smell, touch, etc.).

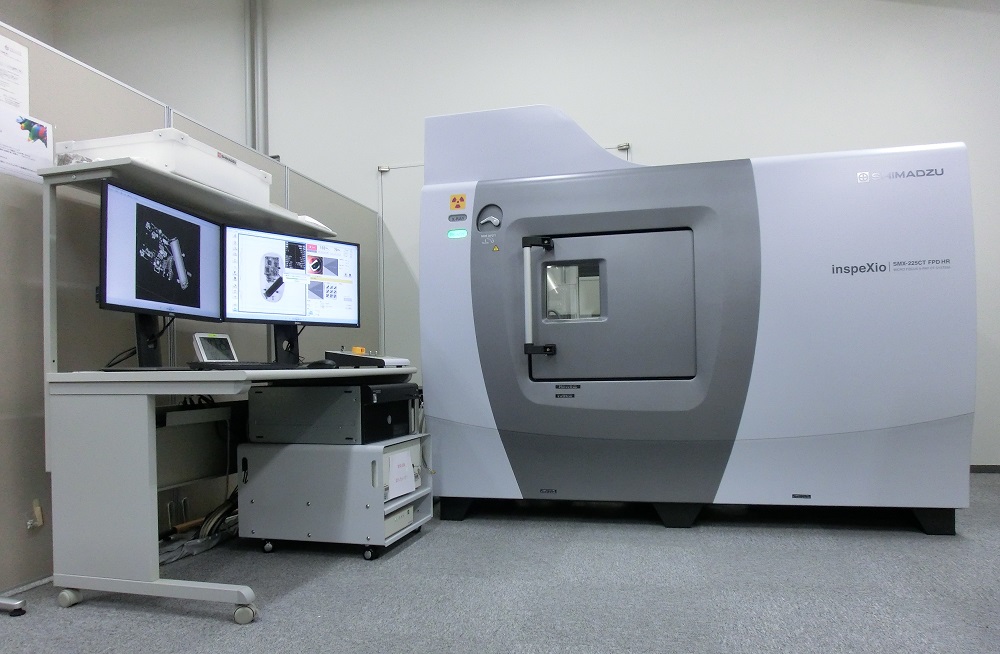

Testing equipment for use environment

X-ray analyzer

Combined temperature, humidity, and vibration testing equipment

Anechoic chamber

Procurement quality initiatives

A finished product is made up of a number of different parts. That’s why the quality of a product cannot be ensured unless the quality of each part is assured. At the JVCKENWOOD Group, we provide all suppliers with the Quality Assurance Manual for Vendors (QAMV), which lists things to check for when ensuring the quality of all parts. In order to ensure that the requirements specified in the QAMV are met, we hold QAMV trainings for our suppliers’ quality management officers. We also conduct quality assessments on suppliers every year and, when a supplier is found to have any quality problem, we work with that supplier to improve quality by conducting a site audit or developing and implementing an improvement plan.

QAMV training at a production facility

Improving quality through human resource development

We see people who engage in product quality work as the key to improving product quality. The JVCKENWOOD Group has established guidelines for employees about the quality-related knowledge and skills they need depending on the type of job they do as well as their experience and position, and regularly provide education and training in line with those guidelines. In fiscal 2023, company-wide quality training was provided to total of 728 employees in 37 sessions. Quality training is also conducted by each business unit when necessary.

We also regularly hold quality improvement contests, where employees across the company compete with each other in their daily activities aimed at improving quality, with an eye to maintaining a high standard of quality methods. Entries to the quality improvement contest are screened through a rigorous review process, and the most outstanding initiative is selected. The winner is presented with awards during quality improvement month.

Software Evaluation Training

Members receiving awards in the Quality Improvement Contest

Manufacturing quality initiatives

We have established a standard design process for commercializing a product that applies throughout the JVCKENWOOD Group. Standardizing the commercialization planning process, documentation formats, action items, terminology, etc. has enabled us not only to improve quality but also to reduce costs and development turnaround time. Each business location has set annual quality targets and follow the PDCA (plan/do/check/act) cycle from policy management to planning, development, auditing, and monitoring in an effort to improve product quality.

Initiatives to improve product development quality

At the product development stage, we use 3D printers to make one-piece parts for high-mix, low-volume products to reduce the part count and assembly man-hours as a way to maintain and improve quality.

Use of 3D printing makes it possible to reduce product weight. It also enables us to make parts at any time and place as long as CAD data for 3D printing is saved, eliminating the need for molds, inventory, and a place to keep them along with cutting costs.

Initiatives Pertaining to Product Safety

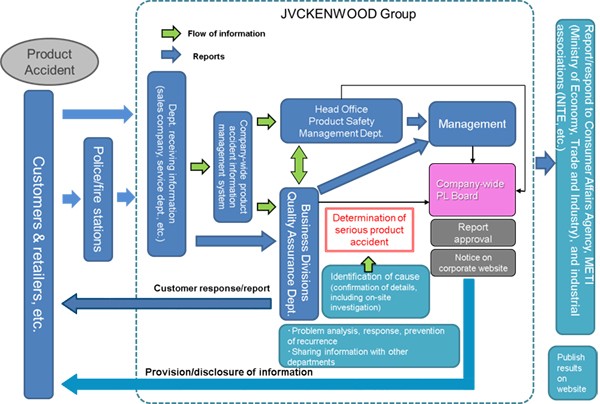

The JVCKENWOOD Group is striving to reduce product safety risks and promptly implement improvements to provide customers with secure and safe products/services in accordance with the Basic Policy on Product Safety and in collaboration with the Head Office’s product safety management department and other relevant in-house departments.

More concretely, we are making product safety risk assessments at the product development stage based on the expected usage environment in order to keep customers safe from serious incidents (fatal accidents, fires, etc.). In the event that information concerning product safety is offered by customers or other stakeholders, we immediately confirm the facts and investigate the causes. If a potential or actual safety issue is identified, we will take steps such as recalling the products in question to prevent/minimize dangers and promptly informing customers and other relevant parties by appropriate methods.

Flowchart for dealing with product accidents

JVCKENWOOD Group Basic Policy on Product Safety

For safe use of products (for customers)

We provide information on correct procedures for safe use of products on each brand’s website and explain these procedures in an easy-to-understand manner to ensure that customers can use JVCKENWOOD Group products safely and securely.

See here for JVC brand & Victor brand products (Japanese)

See here for KENWOOD brand products (Japanese)

Serious Product Defects

Important Notices on the top page of the Group’s official website are used to convey important information on product safety defects or quality issues to customers and other relevant parties.

See here for JVC brand & Victor brand products (Japanese)

See here for KENWOOD brand products (Japanese)

See here for Victor brand products (Japanese)

Initiatives for Product Security

As products are connected to the internet and information systems, and as they become increasingly networked, there is a growing risk of leakage of personal and other information, falsification or destruction of data, and hijacking of products. Working against this backdrop, we believe that enhancing the security of products and services is extremely important and see a strong demand for more secure products and services.

The JVCKENWOOD Group complies with all relevant laws and regulations in accordance with its Basic Policy on Information Security.

We collect security information from wide range sources, including external experts and researchers, and individuals. We have appointed a person and organization in charge of product security that work with business divisions to assure the security of products.

Based on the security information collected, the organization responsible for a product, working under the supervision of the product security officer, looks into products that pose a high security risk and takes appropriate measures that address the potential security impact those products may have on customers.

Additionally, in order to deliver products that our customers can use with confidence, we evaluate possible threats and risks at the product planning stage, and then not only add countermeasure functions to the products, but also conduct pre-shipment inspection using product security vulnerability detection tools. In this way, we implement security measures that take into account the entire product lifecycle, from planning to shipping and disposal. We will stipulate internal rules for assuring product security and conduct in-house training on an ongoing basis as we step up our product security initiatives.

If a serious security vulnerability, incident and/or accident, is found with any of our products, we will promptly report it to the appropriate authorities concerned pursuant to relevant laws and regulations while keeping our customers informed.

Policy on security of information for manufactured and sold by the JVCKENWOOD Group

ISO Certification

The JVCKENWOOD Group has achieved ISO9001 certification, an international standard for quality management systems. We continue to make improvements in our day-to-day business activities so that we better satisfy customers' needs for quality products and services.

| Country | Site/Sector/Business | ||

|---|---|---|---|

| Japan | JVCKENWOOD Corporation | Mobility & Telematics Services Sector | Aftermarket Business |

| OEM Business | |||

| Safety & Security Sector | Healthcare Business | ||

| Communications Systems Business | |||

| Entertainment Solutions Sector | Media Business | ||

| JVCKENWOOD Yamagata Corporation | |||

| JVCKENWOOD Nagano Corporation | |||

| JVCKENWOOD Nagaoka Corporation | |||

| JVCKENWOOD Creative Media Corporation | |||

| JVCKENWOOD Public & Industrial Systems Corporation | |||

| JVCKENWOOD Service (Japan Corporation) | |||

| Malaysia | JVCKENWOOD Electronics Malaysia Sdn. Bhd. | ||

| Thailand | JVCKENWOOD Optical Electronics (Thailand) Co., Ltd. | ||

| Indonesia | PT JVCKENWOOD Electronics Indonesia | ||

Note: Certification has been achieved for major production centers in the sites, sectors, and divisions above.