Occupational Safety and Health

Basic Concept

The JVCKENWOOD Group has established the following Occupational Safety and Health Declaration by top management and the Basic Policy to create a safe, comfortable, and healthy work environment for employees.

Occupational safety and health initiatives cover not only JVCKENWOOD Group employees, but also all those working at Group facilities, including temporary employees and contractors on premises.

<Occupational Safety and Health Policy Statement>

Place Safety and Health Before Everything else

<Basic Policy on Occupational Safety and Health>

The JVCKENWOOD Group is committed to creating a safe and healthy work environment for all workers involved in its business activities in cooperation with various stakeholders, including partner companies, under the Occupational Safety and Health Declaration, which states that it will "Place Safety and Health Before Everything Else."

1. Development and implement plans to set and achieve goals for the prevention of disasters and the maintenance and promotion of health

2. Comply with all laws, regulations, social norms, and internal rules related to safety and health

3. Identify sources of hazards and eliminate or mitigate risks

4. Establish a safety and health management system and clarify roles, authority, and responsibilities

5. Employees and their management discuss and participate in safety and health activities

6. Provide education and training to all employees to raise awareness and encourage self-directed activities

7. Create a safe, healthy, and vibrant working environment.

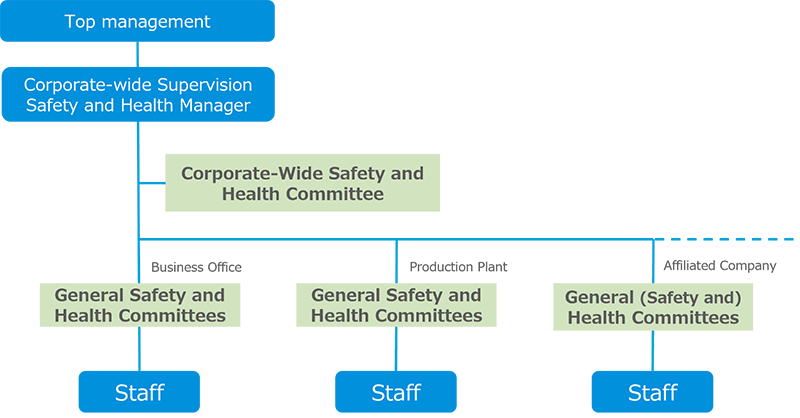

Organization and Management Structure for Occupational Safety and Health

The JVCKENWOOD Group has established a system under which top management ensures that the entire Group promotes occupational safety and health activities under a common policy.

The Corporate-Wid Safety and Health Committee meets regularly at least once a year. Labor and management work together to investigate and deliberate on issues at the Company-wide level regarding basic measures for preventing worker hazards and health hazards and preventing occupational accidents. They also set annual company-wide safety and health activity goals and priority action items, which are then rolled out to each business site, sales office, and affiliated company. Each business site and affiliated company has a Safety and Health Committee (or Health Committee) according to its size in accordance with laws and regulations.

Meetings are held regularly at least once a month to promote occupational safety and health activities that are appropriate to the conditions at each business site. At sales sites with less than 50 employees, the higher-level organizations provide information on safety and health, appoint a safety and health promoter depending on the number of employees, and provide a forum to receive workers' feedback on a regular basis.

Occupational Safety and Health Management Initiatives

Occupational Safety and Health Management Systems

JVCKENWOOD has established a further system to prevent injuries and illnesses of people involved in its business, to systematically and continuously improve the workplace environment where people can do their job safely and with vitality and to autonomously promote occupational health and safety management.

None of our sites within Japan currently have ISO45001 accreditation, but we are progressing initiatives toward obtaining it in FY2026.

Identification and Risk Assessment of Occupational Health and Safety Hazards

When new equipments are developed or deployed, or when the work environment or methods are changed due to relocation, risk assessments are conducted in accordance with internal rules to eliminate sources of hazard or take measures to mitigate the risk of harm. Furthermore, to prevent occupational accidents caused by chemical substances, in accordance with the April 2022 amendment of the Ordinance on Industrial Safety and Health and other laws, we have established internal rules to ensure that risk assessments are performed when new substances in scope are introduced or when operations are changed. We have also established and promoted awareness of a management system to ensure that measures to minimize exposure to chemical substances are properly implemented.

Status of Training for Workers on Occupational Health and Safety

To raise awareness of occupational health and safety, in addition to the statutorily mandated training, since FY2022 we have included and implemented in our internal rules the implementation of occupational health and safety training at least once a year for domestic Group employees and temporary employees. Recognizing the fact that some employees have lost work time due to accidents incurred while commuting, as one of the measures against absenteeism, we select and implement effective training themes based on the previous year's occupational accidents. These include not only work-related accidents but also commuting accidents.

Units: persons

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Number of employees who took the occupational safety and health training | 3,289 | 3,294 | 3,536 |

Status of Discussion Forums/Communication between Labor and Management on Occupational Safety and Health and Safety (Safety and Health Committee, etc.)

Our occupational health and safety initiatives cover not only employees of the JVCKENWOOD Group, but also all persons working at Group facilities, including temporary employees and onsite contractors. As well as complying with the Industrial Safety and Health Act and related laws, each Group company, office, and site holds a Safety and Health Committee meeting or a Health Committee meeting at least once a month on a regular basis in accordance with laws and regulations, and labor and management work together to create a safe and healthy workplace.

Augmenting the legally mandated periodic patrols by safety managers, etc., at workplaces above a certain size, safety patrols are conducted by committee members in addition to industrial physicians and Safety and Health Manager after Safety and Health Committee meetings. Corrective measures are taken for issues discovered in the workplace from the perspective of occupational safety and health or fire and disaster prevention, while listening to the opinions of committee members who represent workers.

Scene from Safety Patrol

Safety and Health Committee meeting

Supply Chain Safety and Health Initiatives

The JVCKENWOOD Group developed the JVCKENWOOD CSR Procurement Guidelines in 2017, including specific provisions to promote safety and health efforts in the supply chain. These guidelines have been explained at Partners Meetings to deliver parts suppliers in our supply chain. They have also been asked to take voluntary and proactive measures to realize CSR procurement.

We have also declared that we will work to build a new partnership by promoting cooperation and coexistence and co-prosperity with our suppliers in the supply chain and with businesses that create value.

For details, please see Sustainable Procurement

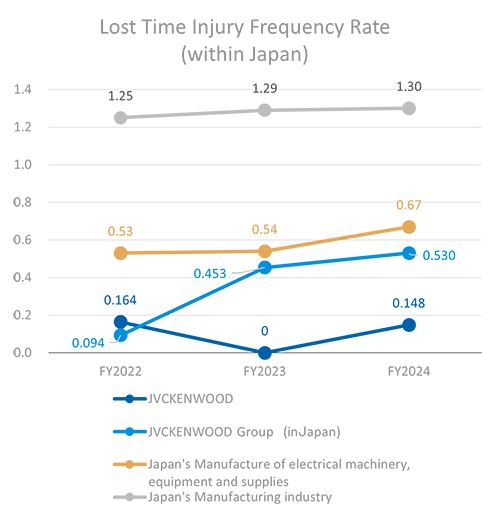

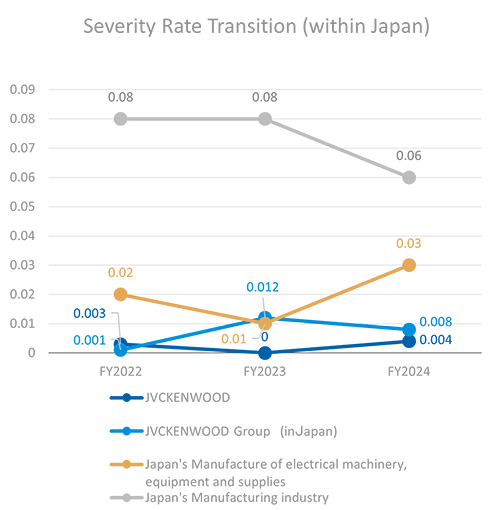

Frequency Rate of Lost Time Injuries and Severity Rate of Lost Time Injuries

The FY2024 occupational accidents overview for the JVCKENWOOD Group within Japan was that the number of accidents necessitating time off work increased by one year on year and the frequency increased, but the severity rate decreased. Six workplace accidents requiring time off work occurred across the entire Group within Japan, four of which were due to falls or tumbles (such as falling down stairs). A total of 11 workplace accidents occurred including those which did not require time off work, half of which were due to falls or tumbles, and almost all of which involved staff aged over 50 who were visiting sites away from Company premises. In response, we have provided all employees with safety and health education about how to prevent falls caused by decreased physical capability with age. We will continue to advance our initiatives with the aim of zero occupational accidents again in FY2025.

(JVC Kenwood Group in Japan)

| FY 2022 | FY 2023 | FY2024 | |

|---|---|---|---|

| Frequency rate of lost time injuries*1 | 0.094 | 0.453 | 0.530 |

| (Manufacturing industry) | 1.25 | 1.29 | 1.30 |

| Severity rate of lost time injuries*2 | 0.001 | 0.012 | 0.008 |

| (Manufacturing industry) | 0.08 | 0.08 | 0.06 |

*1 Frequency rate of lost time injuries: Frequency rate of accidents, which is calculated using the following formula: number of casualties due to occupational accidents / total actual working hours × 1,000,000.

In this table, work-related accidents caused during the execution of work are limited to the number of casualties caused by work accidents resulting in absence from work of one or more days and lost a body part or a bodily function due to the accident, excluding commuting accidents other than the execution of work and delayed-onset accidents (in accordance with the Ministry of Health, Labour and Welfare Survey on Industrial Accidents)

*2 Severity rate of lost time injuries: Severity rate of accidents, which is calculated using the following formula: total lost-work days / total actual working hours × 1,000.

Types of Work-Related Accidents, Number of Incidents and Lost Time (FY2024)

| Type of accident | Fall | Falling down | Crash | Pinching and entanglement | Cut / rubbing | Contact with hazardous agents | Traffic accidents (road) | Reaction of movement / strained movement | Total |

|---|---|---|---|---|---|---|---|---|---|

| Work-related accidents | 2 | 4 | 1 | 2 | 1 | - | - | 1 | 11 |

| Accidents while commuting | - | 4 | - | - | - | - | - | 2 | 6 |

| Total | 2 | 8 | 1 | 2 | 1 | - | - | 3 | 17 |

| Type of accident | Days lost due to work-related accidents | Time lost due to work-related accidents (per 1 million hours)* |

|---|---|---|

| Work-related accidents | 107 days | 73.28 hour |

| Accidents while commuting | 38 days | 26.03 hour |

| Total | 145 days | 99.31 hour |

*Time lost due to work-related accidents (per 1 million hours) = (number of scheduled working hours lost due to work-related accidents / total actual working hours) x 1,000,000

Number of Fatal Accidents and Fatalities

(JVC Kenwood Group in Japan)

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

Fatal accidents (Fatalities) |

0(0) | 0(0) | 0(0) |

Other initiative

Initiatives to Prevent Traffic Accidents and Traffic Safety

The JVCKENWOOD Group has introduced an in-house driving permit system under which company-owned vehicles (including rental cars used for business purposes) are issued to those who meet certain conditions, such as their history of traffic violations and accidents over the past five years. Unskilled drivers with a high risk of automobile accidents are not permitted to drive. We have also taken measures to prevent traffic accidents by requiring all employees, including those who commute by personal car, to attend a safe driving seminar once a year, installing connected-type dashcams in all company-owned vehicles, and requiring employees at business centers that have not appointed a safe driving manager to voluntarily check for intoxication using an alcohol detector.

In FY2024, there were no occupational accidents due to traffic accidents while at work or commuting to work. We will continue to promote traffic safety through initiatives such as safe driving seminars and safety and health education.

Fire and Disaster Prevention

In the event of a natural disaster, fire, or other serious accident, the safety of our employees, their families, and visitors is our top priority. We have established a "Comprehensive Disaster and Accident Preparedness Manual" to ensure an appropriate and prompt first response system in our Business Continuity Planning (BCP). The manual specifies fire and disaster prevention systems, basic policies, and action guidelines for during business as usual and in the event of a disaster or accident. Based on the manual, the Company conducts regular drills for the administrative and inspection of materials and equipment during business as usual, safety confirmation drills for telework and business trips, and reporting and evacuation drills in the event of a disaster.

Furthermore, risk surveys are conducted every one to five years by external experts in response to changes in the nature of operations and layout changes at our business sites, including overseas locations. Preventive measures are taken in response to findings concerning occupational safety and health, fire prevention, and disaster prevention to promote the creation of safe and secure work environment. As part of safety and crisis management measures for employees working or traveling overseas, we distribute daily safety information by major overseas countries and cities on our intranet portal, which contributes to the avoidance of hazardous risks, and we have established a 24-hour support system.

Joint disaster drill by six neighboring companies with the full cooperation of the Yokohama City Fire Department (Hakusan Business Center)

Lifesaving training using AEDs under the guidance of Yokohama City Fire Department personnel